How a bleeding fabric

took Karle from

Madras to Manhattan.

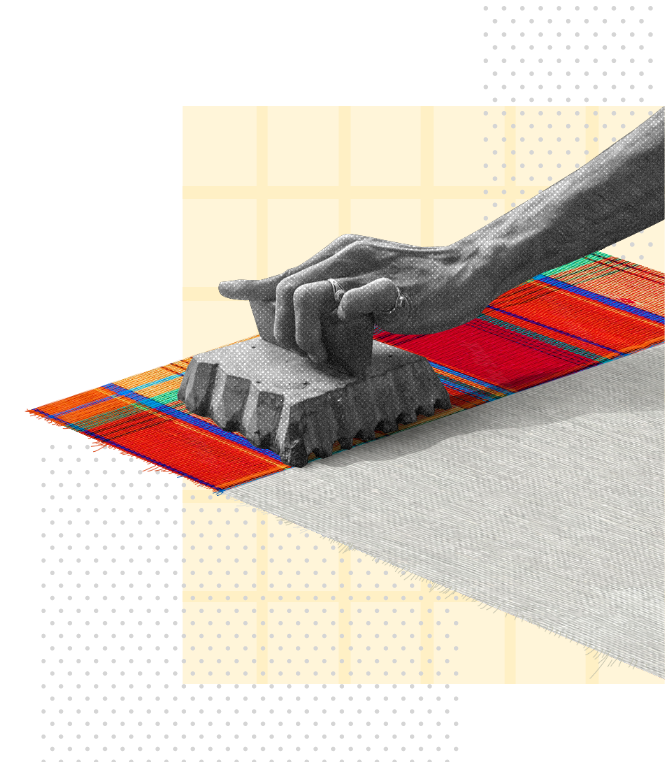

Lungi: The Origin Story

In the 12th century, a village in Madraspatnam started weaving soft fibers from native trees & block printing them with bright colour patterns. Worn around the waist, this came to be known as the Lungi!

Lungi: The Origin Story

In the 12th century, a village in Madraspatnam started weaving soft fibers from native trees & block printing them with bright colour patterns. Worn around the waist, this came to be known as the Lungi!

Thanks to the East India Company, this fabric travelled to Africa & Middle-East and was worn as headscarves and ceremonial attire. The fabric had a value equal to gold and was worn by royals and used in ceremonies.

Post-Independence Blues

The Indian Textile Industry was still catching up to international quality standards as it lacked industrialization and continued to use traditional manufacturing techniques. To promote the Indian handloom industry, the All India Handicrafts Board was setup in the 60s. The strategic shift soon helped garner export orders from the US.

Post-Independence Blues

The Indian Textile Industry was still catching up to international quality standards as it lacked industrialization and continued to use traditional manufacturing techniques. To promote the Indian handloom industry, the All India Handicrafts Board was setup in the 60s. The strategic shift soon helped garner export orders from the US.

Bleeding Madras

By the 60’s Madras Checks had taken the American fashion stage by storm. But, the harsh chemical detergents used in the US made the natural vegetable dyes to bleed. This caused an initial uproar with the customers.

Marketing genius David Ogilvy converted this problem into an opportunity by coining ‘Guaranteed to Bleed’ for Brooks Brothers, one of the largest importers of this fabric. Customers now wanted this ‘miracle handwoven fabric from India’ that changed colors with every wash and went well with faded denims.

Marketing genius David Ogilvy converted this problem into an opportunity by coining ‘Guaranteed to Bleed’ for Brooks Brothers, one of the largest importers of this fabric. Customers now wanted this ‘miracle handwoven fabric from India’ that changed colors with every wash and went well with faded denims.

Imperfections lead to Perfections

The demand for Madras Checks gave India the perfect opportunity to enter international markets. Karle Group took this opportunity to set up its first garment manufacturing factory and paved the way to fulfil its mission of creating employment post-Independence.

‘Bleeding Madras Checks’ gave Karle Group an international footprint and forged strategic partnerships with renowned fashion houses.

‘Bleeding Madras Checks’ gave Karle Group an international footprint and forged strategic partnerships with renowned fashion houses.

The company immediately realised that to succeed in the volatile fast-fashion business, improved quality standards and the assembly-line production technique would be the cornerstone of

organisational longevity and legacy.

Checks x India x Karle

The history of the Madras Checks was closely intertwined with the history of India and its textile industry. It also sets the tone for the company’s growth, the way the company did business and laid the foundation for its 50-year stint as a leading garment exporter.

Checks x India x Karle

The history of the Madras Checks was closely intertwined with the history of India and its textile industry. It also sets the tone for the company’s growth, the way the company did business and laid the foundation for its 50-year stint as a leading garment exporter.